.jpg)

Hay Animal Feed Pellets (Equipment & Benefits)

Hay refers to dried grass used as livestock fodder. It is fed to especially pasturing animals, for instance, sheep, goats, horses and cattle when grazing is unobtainable due to harsh climatic conditions. Pellets are renewable organic matter made from compressed hay and other biomass; pellets are used to balance the nutrition for grazing animals. Also, the pellets are very nutritious and easy to store hence can maintain the animals in famishing times.

ABC Machinery is a professional feed pellet mill machinery manufacturer that is dedicated to the research and development of environmentally friendly animal feed pellet processing equipment. Welcome to contact us directly to get the more information on making animal feed pellets from hay!

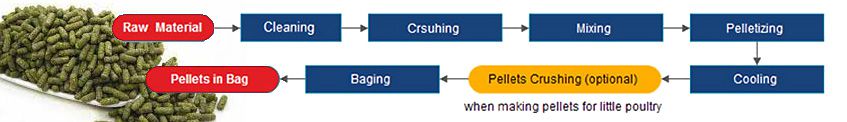

Hay Pellets Production Process

The crucial technique of making pellets from hay includes:

Adjusting the water content of the hay : One must measure the water content of the hay first, and then add water to the processing requirements of the water content. According to the extensive research that has been made, optimum water content for forage grass is 13% -15%.

Pellet feed mill is usually used for making pellets from hay for its effect of mixing by a feed mixer machine and squeezing out in the process of rolling grass. The temperature of the pellets meal can extend to 80 degrees under normal conditions. However, water content frequently abbreviates by 3%-5% from the high temperature hence cooling the room temperature. The water content of the hay meal after cooling is not greater than 11% - 15%.

Due to low water content, the pellets made from hay are worth long term storage without getting musty. All sorts of dissimilar nutrients pellets can be combined to comply with the nutritional requirements of the respective livestock, and the pellet size is changeable by the rolling machine by the prerequisites.

Hay Pellets Production Process

Hay Animal Feed Pellet Machine

If you are planning to make animal feed pellets from hay , there are two options for you.

Small scale feed pellet machine: The current hay pellet machine is typically compiled of stirring, pressure, transmission and the frame sections.

Large scale animal feed pellet machine: you can take the following project for reference. It is designed with a ring die feed pellet machine and automatic batching system, so that to ensure high efficiency.

| Pellets meal fineness pressed | less than 1 mm |

|---|---|

| Particles cooling method | natural cooling type |

| Sieve aperture | 8, 6, 4.5 and 3.2 mm in diameter |

We can also offer processing machines and solutions for hay feed pellets, and just contact us for detailed equipment details and costs!

Factors Affecting the Output of Animal Feed Pellet Machine

Equipment

For yield of diverse pellets feeds for livestock in the making of pellets from hay technology in addition to maximum utilisation of the change per unit flow.

What’s more, the following should also be included in pellets feed machine:

Flux topping – this includes green grass hay and straw stalks which should vary 57% - 60%.

Concentrates – they include corn, sorghum, oats and wheat bran which should vary from 38 – 42%.

Minerals and vitamins - they should range from 1% and 2% of total feeds as the component.

Addition Agent

The feeds should then be squeezed into pelleted feeds with the feed pressure machine and also in every 100 kilogrammes of above feeds, 17 kilogrammes of water and 150 ml, 37% molar formalin should be added to improve on quality, nutritional value and digestible hossmachine and also in every 100 kilogrammes of above feeds, 17 kilogrammes of water and 150 ml, 37% molar formalin should be added to improve on quality, nutritional value and digestibility.

Raw Material

Experimentally done, an eight-month-old Lamb feeding on pellet feeds gains 200 grams weight per day, and this shows that feeding a fat lamb with pellets made from hay is a workable method to boost the ontogenesis of livestock and moreover the aquatic animals.

Hay Feed Pellets

Video of animal feed pellet machine

Benefits of Hay Pellets Feed

- High transubstantiate rate –more weight gains, egg, more milk is apparent with fewer pellets.

- Only belittled volumes needed.

- Supports animal growth and development during harsh climatic conditions.

- The quality of hay is improved by the chemical treatment applied.

- Spreads the source of the fodder.

- Pellets made from hay are indeed significant in supporting livestock lives and development.

On the whole, hay is an important raw material for making pellet feed for animals, and it also has many nutritional values. Besides, since the demand for more animals is still growing as well, the need for more feed is high, and therefore there are still more areas yet to be exploited in the animal feed processing industry. Just tell us your needs and requirements, we believe that we can offer the BEST solution to satisfy you!