Vital aspects to consider for wood pellet plant design

Here are some of the very necessary steps you should take before putting up a wood-pellet plant.

- Choosing a professional consultant

Looking for a professional wood pellet consultant should be the very first step to take. Such a consultant can help minimize delays in the design process due to unnecessary mistakes and unanticipated costs. He/she should be innovative, experienced and unbiased in the search for the best solutions for their clients. The consultant should give prior-studies to the biomass fuel, feasibility studies, preparation of permit application, project management, process optimization, detailed engineering & design and even help in the project’s troubleshooting process.

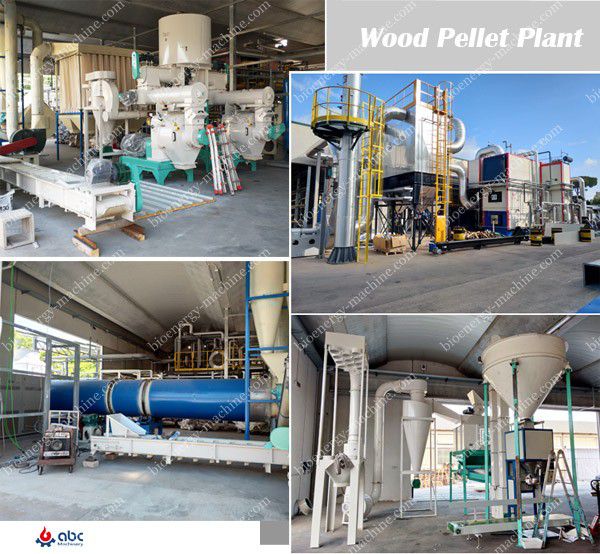

With respect to the available resources and plant site; the consultant should advise you on dimension and size of the facility. The plant design should also factor in raw material delivery, raw material storage system, pre-processing system, drying system, pelletizing, cooling and packaging systems.

- Site design

Once the preliminary plant design factors have been tabulated, the next thing is to get the detailed pellet plant and layout drawn. The choice of required production steps and the market survey to locate the ideal wood pellet-plant technology can then be conducted. A more reliable wood pellet equipment supplier that offers the best of operational cost should also be sought from the competitive market.

To ensure an effective wood pellet-plant design, many aspects of the materials used to the equipment and the complete working process should be well analyzed.

- Understanding the characters of the material

Wood pellet production usually uses the materials that are difficult to compress hence the machines used operate at low speed. The equipment used such as the wood pellet mill has distinctive features that work to provide more torque & power.

Since grass is an easier material to compress as compared to wood, the grass-pellet operates at a higher speed. The wood pellet equipment also has more load on the bearings and consumable parts such as the die and rollers.

- Choosing the right type of pellet mill

The choice of equipment used to produce the pellets depends on the raw materials being processed. The particle size, material density and the moisture content all affect the quality and productivity of the pellets in one way or the other.

There are two major designs of the pellet mill; the ring die and the flat die designs. The latter is mainly used for small scale-pellet mill while the ring-die design is used mainly for large-scale pellet mill.

The equipment’s crushing system should be designed to suit all the necessary parts. The rotary dryer and the cooling system should be up and running to the optimal levels to avoid poor quality pellets.

The final process in the processing of wood pellets involves sieving and packing. The sieving process separates the granules of the damaged/ broken pellets from the complete ones. The whole machinery should be full and intact to make sure the sieving & packaging process are all taken care of.

- Necessary machinery

Some of the essential machinery include conveyors, rotary screen, Rotary and cooling dryers, buffer bin, pellet mill, mobile and discharging belts and the electronic control systems. These are just a few of the machinery needed for the effective running of the plant.

Advantages of the wood pellet production

The processing procedures include; crushing of the biomass materials, drying, mixing the materials with additives then pressing. Here are some of the technical parameters and advantages of the wood pellets.

- Wood pellets are more affordable as compared to the petrol products.

- Wood pellets also have a policy advantage as compared the carbon and petro-fuel products in the market. Development of the biomass pellets complies with the global energy policy.

- Most of the raw materials needed are readily available. The equipment used also has low energy consumption and low investment making it possible to realize profits with less of a hassle.

Finding the right consultant for your project should be your first priority. The proper choice of raw materials, technology, and equipment is all you need to get the wood pellet plant design up and running.