- Project Item: Chicken Feed Pellets Production Plant Setup in Uganda

- Capacity: 1-2TPH

- Raw Materials:corn, soybeans, sunflower seed cake, soybean meal, premix, fish meal

- Feed Pellet production Processing: Crushing,Mixing, Pelletizing, Cooling and Packaging, etc.

- Application: It is designed for processing both poultry feed and livestock feed, including chicken, duck, goose, pigeon, rabbit, alpaca, camel, cattle, deer, donkey, sheep, goat, horse, etc.

1-2ton/h Chicken Feed Pellet Production Project Built in Uganda

A prominent feed producer from Uganda has introduced a complete set of animal feed processing equipment from ABC Machinery. Specifically designed for pelletizing feed from grains and corn, this commercial animal feed production line provides balanced nutrition for poultry and livestock.

For more information and get free chicken feed processing quotation, please contact us now!

Invest 1-2 TPH Chicken Feed Pellets Production Project in Uganda

Chicken Feed Plant Installation in Uganda

Chicken Feed Pellet Making Plant Layout

Chicken Feed Pre-processing Machines

1-2tph Chicken Feed Pellet Line Instruction in Uganda

Chikcen Feed Pellet Mill Test On-site

Feed Pellet And Mixing Machine at Factory Price

Feed Pellets Screening Machine for Chicken

Chicken Feed Pellets Packing Machine

Formed Chicken Feed Pellets

Final Chicken Feed Pellets Product

The 1-2 ton per hour animal feed pellet production line adopts a streamlined and efficient process to create premium chicken feed pellets. Beginning with the crushing of raw materials, it proceeds to meticulous mixing for uniformity. The mixture is then transformed into feed pellets using advanced feed pelleting technology, ensuring ideal density and shape. Following this, the pellets undergo cooling to preserve their quality and extend shelf life. Finally, the pellets are meticulously packaged for sale to local poultry and livestock farms.

Invest in our top-tier animal feed pellet production line today to establish a dependable and efficient poultry feed production facility in Uganda!

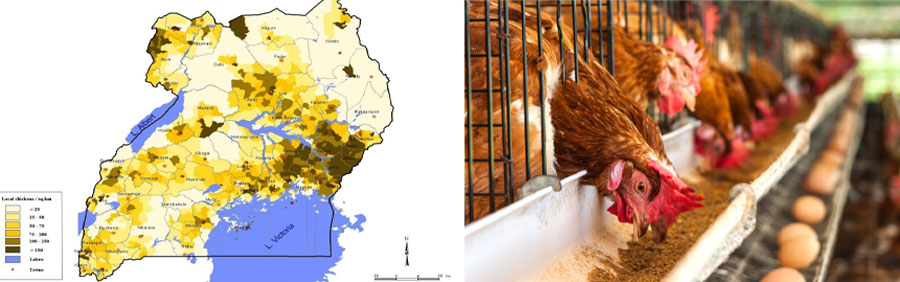

Market Demand for Chicken Feed Pellet Production in Uganda

High Investment Potential of Chicken Breeding Market in Uganda

Investing in establishing a 1-2 ton per hour chicken feed pellet production plant in Uganda is a business opportunity with tremendous potential.

The poultry farming industry in Uganda is growing at an annual rate of approximately 6-7%. Industry statistics indicate that Uganda's annual chicken feed consumption is estimated to be around 500,000 metric tons, leading to an increasing demand for high-quality feed. However, The current supply of chicken feed in Uganda falls short of meeting the demand.

Starting a chicken feed pellet processing plant Business not only fulfills local market needs but also enables the provision of high-quality feed to neighboring regions, expanding market share. By leveraging the growing demand and supply gap, investors can capitalize on this opportunity for sustainable growth and profitability.

Key Steps in Setting Up a Chicken Feed Pellet Manufacturing Plant

- Site selection: Choose a location within 50 kilometers of major transportation hubs to ensure convenient transportation. Ensure the site can accommodate the storage of at least 500 metric tons of raw materials per month, meeting the demand for continuous production. This will also ensure a stable supply of raw materials, as the proximity to transportation hubs facilitates easy procurement.

- Equipment procurement: Purchase efficient chicken feed pellet production equipment with a minimum output capacity of 1.5 metric tons per hour. This will ensure high production efficiency and consistent product quality, meeting the demand for high-quality chicken feed in the market.

- Raw material procurement: Cooperate with local farmers to ensure the stability and quality of raw material supply. Require raw materials to meet a minimum protein content of 18% to ensure the nutritional quality of the chicken feed pellets.

- Production management: Establish a scientific production management system that can process raw materials within 48 hours of procurement. This will ensure smooth production operations and maintain the freshness and nutritional value of the feed pellets. Regular monitoring and adjustment of the production process will help optimize efficiency and quality control.

An investor established a 1-2 tons/hour chicken feed pellet production plant in Uganda and ensured the supply of raw materials by cooperating with local farmers. After careful management, production efficiency has been continuously improved, product quality has been recognized by the market, and considerable economic benefits have been achieved.

If you're interested in this chicken feed pellets production plant project in Uganda and are looking to start a business in chicken feed or poultry feed productionPlease get in touch with us!